Capacitors

Active Signal Technologies, in collaboration with the New York State College of Ceramics at Alfred University (NYSCC at AU) has developed a new family of ceramic dielectrics for use in next generation military avionics and other high temperature applications.i,ii Starting with the bismuth sodium titanate {(Bi0.5Na0.5)TiO3, NBT} system, traditionally considered a candidate for lead-free piezoelectric formulations, the team investigated numerous formulation and processing modifications to meet application requirements. This included an exhaustive matrix of substituents on the A and B site of the perovskite lattice together with secondary additives, to optimize electrical performance while minimizing piezoelectric strain. The desired electrical performance was broadly defined as room temperature dielectric constant on the order of 1000 or better, loss below 5% and resistivity better than 1X10E11 Ohm-m across the operating temperature range, low dispersion, low voltage coefficient and low temperature coefficient (preferably featuring a long temperature plateau with relatively little change in capacitance). Within these performance constraints, three different classes of material were developed, each exhibiting high temperature performance characteristics far exceeding anything available commercially or reported in the literature.

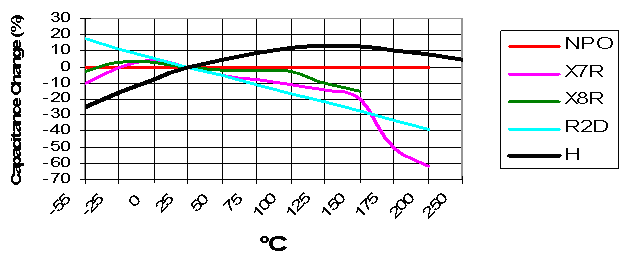

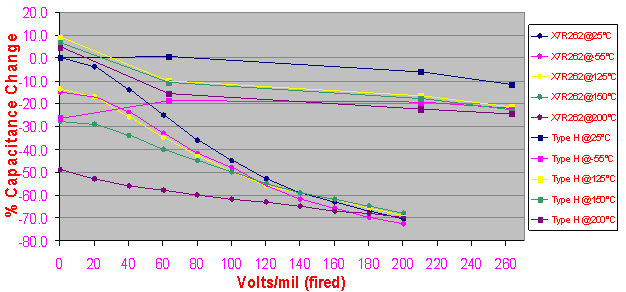

The first was targeted as a replacement for current avionic power-conditioning capacitors with the advantage of reduced voltage coefficient and a useful temperature range above the present mil spec requirement of +125ºC. The selected material has been commercialized by Novacap and capacitors fabricated from it are available from them by e-mailing Novacap and requesting Type H dielectric capacitor information. The Type H capacitors exhibit less than 15% variation from nominal ambient temperature value between -20ºC and +200ºC -- see Figure 1. Moreover, they have loss below 5% (at frequencies up to 100 kHz) over the same temperature range and retain usable capacitance well beyond +200ºC. At the low end of the military temperature range (-55ºC) the capacitance drops by about -27% of nominal hence falling outside the strict definition of X7R (±15%). However, a more meaningful comparison between X7R and Type H is obtained by including the effects of both temperature and voltage stress. Thus at -55ºC and operating stress of 150 V/mil the capacitance of a typical X7R has dropped by about -65% from nominal whereas the decrease with Type H is less than -20% -- see Figure 2. At the high temperature end the combined effects are obviously more pronounced because of the very low voltage and temperature coefficients. For X7R at +200ºC capacitance will typically drop by about -50% from nominal at low operating voltage stress, approaching -70% at higher stresses, whereas with Type H operating at 150 V/mil the drop is closer to -20%.

The second dielectric class (very high temperature type) was aimed at high temperature applications (+150 ±100ºC to +350 ±100ºC) where it was possible to remove the constraint of retaining usable capacitance at very low temperatures. Since high temperature performance is the inherent strength of the NBT system, there were large numbers of formulations that looked promising in this range (permittivity plateaus between 2000 and 4000 with typically ±15% permittivity variation over wide temperature ranges), even extending to +450ºC and beyond. These compositions are also covered by our patent but have not been commercialized.

The third dielectric class (stable capacitance over a wide temperature range [-55ºC to +300ºC]) was designed for use where invariant capacitance, low dispersion and low loss are critical. This should be compared with commercial NPO type dielectrics that typically have relative permittivity below 200 and temperature coefficients <1000 ppm/ºC. Formulations currently in development by Active Signal have permittivity >1500 (±15%) from -55ºC to +300ºC, dispersion <5% at 1KHz and loss <0.01% above 70ºC.

For further information on very-high temperature stable capacitance dielectrics interested parties should contact Arthur Cooke or Frank Duva.

Figure 1. Capacitance change with temperature comparison of Type H with other dielectrics.

Figure 2. Capacitance change with electric field comparison of Type H with X7R dielectric.

i “Advanced High Temperature Dielectric Material”, Active Signal Technologies Final Report to Defense Threat Reduction Agency for Contract No. DTRA01-03-C-0031 (2007).